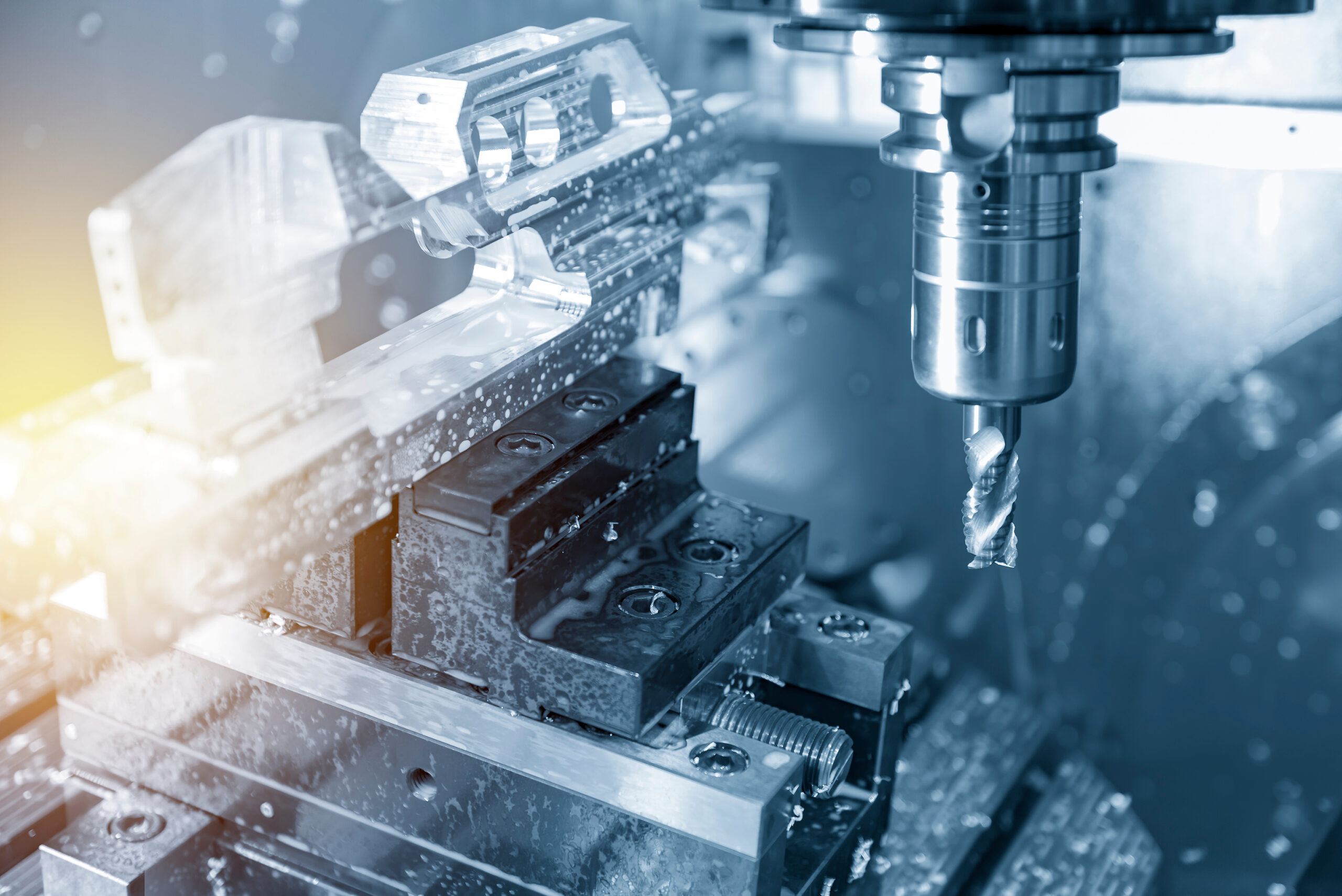

Pro-Tech CNC Limited has a wide range of the latest CNC Turning & Milling machinery

PRECISION ENGINEERING

& CNC SErvices

Contact us

PRECISION ENGINEERING.

Pro-Tech CNC Limited established in 2003 by Steve Hatcher & David Betteridge in a small workshop in Stoke Golding which they aptly called the shed, as the business grew in 2006 they move to their current location in Market Bosworth.

Pro-Tech CNC Limited continued to provide high quality engineering solutions to many international clients and markets, using CNC machinery and CAD CAM technology.

Today Pro-Tech CNC Limited continues to thrive and has been able continue its growth and determination to bring young blood back into manufacturing, we work closely with local colleges to bring through new apprentices.

Pro-Tech CNC Limited remains a highly respected company supplying machining and turning solutions to a wide range of markets including the Printing, Motorsport, Automotive, Aerospace, Commercial and Marine industries.

We look forward to helping you with your next project.

YOUR DESIGN, MACHINED.

Here at Pro-tech CNC we have the ability to take your CAD designs from a design to a fully machined final product. Pro-tech achieves this though its many specialised machines and highly trained engineers.

Today Pro-Tech CNC Limited is a highly respected company supplying a wide range of markets including the Printing, Motorsport, Automotive, Aerospace, Commercial and Marine industries.

Let's Work Together.

Pro-Tech CNC Limited can provide help with

- Design

- Development

- Quotations

- CNC Machining

- Quality

- Product stocking system