OUR RANGE OF SERVICES

Contact us today

WE offer a wide range of services

Pro-Tech CNC Limited have the capacity to Turn components from 6mm to 300mm in diameter and up to 500mm in length, our Milling footprint can reach up to 1250mm x 500mm.

We have always taken the opportunity to invest in new machinery with the introduction of the facility for 5 & 7 AXIS Machining.

CNC Turning

Our state-of-the-art CNC lathes with both driven tooling and sub-spindle options enable us to provide a turning capacity of up to 500mm in length and 300mm diameter. Following continuous investments in industry leading technology with the introduction of 7 Axis machining lathes, we are able to provide our customers with quick quotation and turnaround times for precision turned parts and quality machined components.

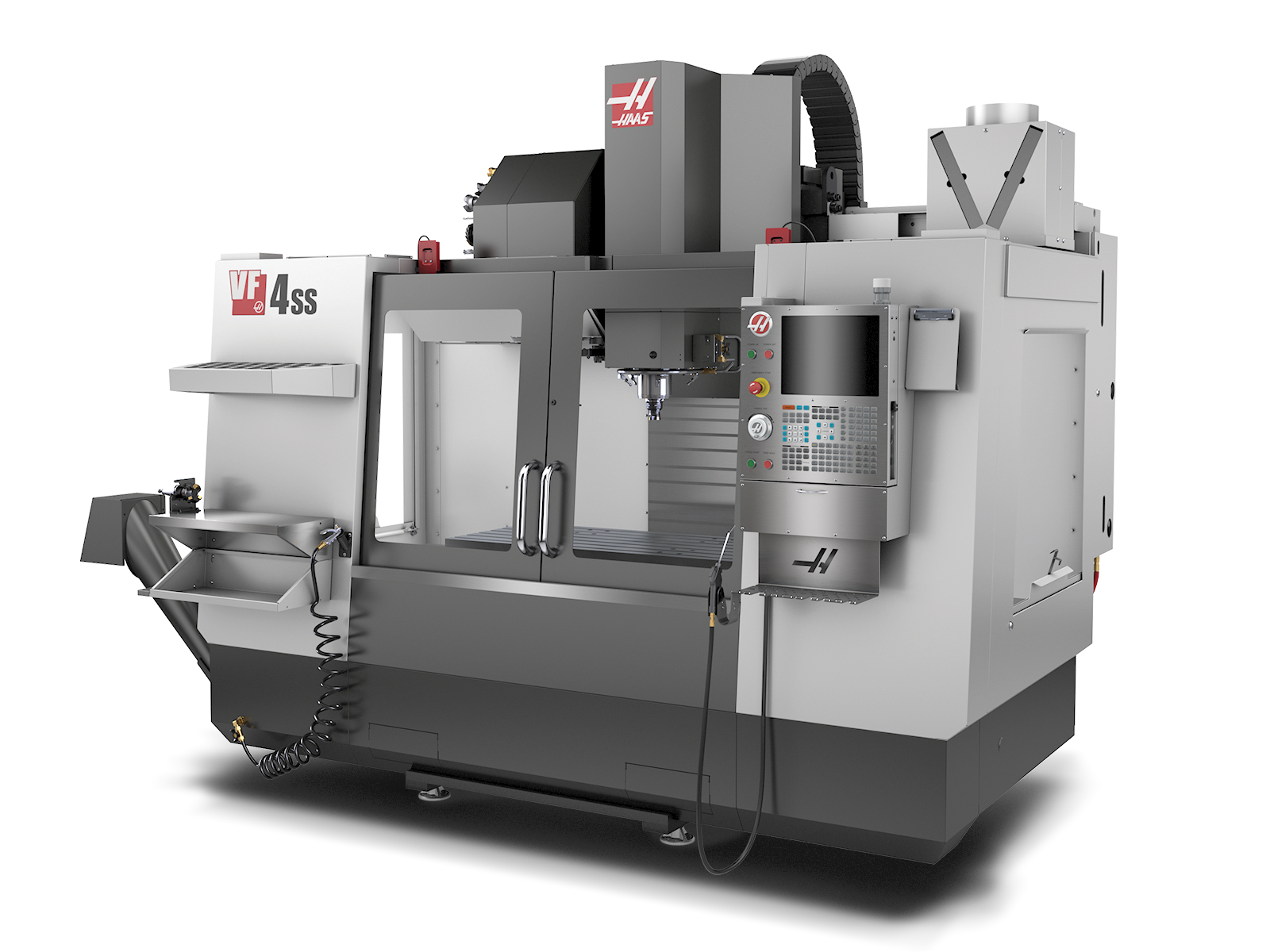

CNC Milling

Quality

Pro>-Tech CNC Limited have highly trained engineers who work with one of the latest innovative Measurement Systems and have instilled the need for quality engineering, the company has been accredited with ISO 9001:2015 certification.

Faro Quantum 3

The Faro Quantum probe can digitize interchangeably without having to remove either component. Users can digitize simple features with the Arm’s hard probe and seamlessly scan across diverse surface materials regardless of contrast, reflectivity or part complexity without any special coatings or target placement.

Faro Quantum 3 provides an additional Axis of Rotation for non-contact Laser Line Probes or curved probes.

Mounting options available: Magmount, Tripod and Vacuum Mounting.

Let's Work Together.

Pro-Tech CNC Limited can provide help with

- Design

- Development

- Quotations

- CNC Machining

- Quality

- Product stocking system